Stepper Motor Driver - Single Axis (Peak 4.5A) TB6600

- Was RM58.00

-

RM30.00

- Product Code: TB6600 4.5A

- Availability: In Stock

Features

Specifications

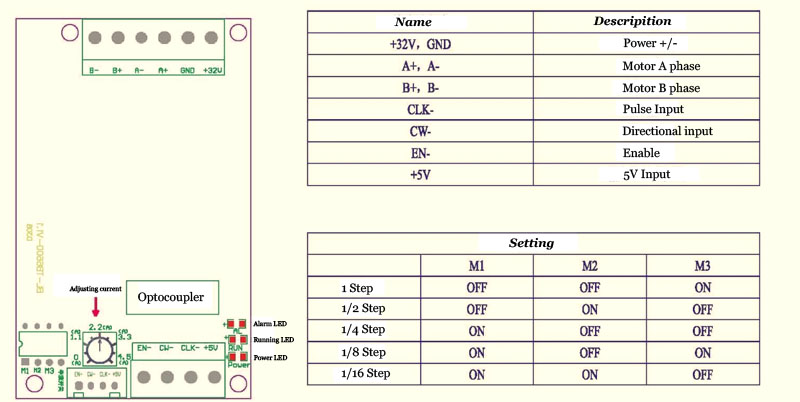

* Recommend to use a 10k potentiometer.

The HCMotor library required for the above sketches can be downloaded from our support forum here:

Arduino sketch

/* Include the library */ #include "HCMotor.h" /* Pins used to drive the motors */ #define DIR_PIN 8 //Connect to drive modules 'direction' input. #define CLK_PIN 9 //Connect to drive modules 'step' or 'CLK' input. /* Set the analogue pin the potentiometer will be connected to. */ #define POT_PIN A0 /* Set a dead area at the centre of the pot where it crosses from forward to reverse */ #define DEADZONE 20 /* The analogue pin will return values between 0 and 1024 so divide this up between forward and reverse */ #define POT_REV_MIN 0 #define POT_REV_MAX (512 - DEADZONE) #define POT_FWD_MIN (512 + DEADZONE) #define POT_FWD_MAX 1024 /* Create an instance of the library */ HCMotor HCMotor; void setup(){ //Serial.begin(9600); /* Initialise the library */ HCMotor.Init(); /* Attach motor 0 to digital pins 8 & 9. The first parameter specifies the motor number, the second is the motor type, and the third and forth are the digital pins that will control the motor */ HCMotor.attach(0, STEPPER, CLK_PIN, DIR_PIN); /* Set the number of steps to continuous so the the motor is always turning whilst not int he dead zone*/ HCMotor.Steps(0,CONTINUOUS); } void loop(){ int Speed, Pot; /* Read the analogue pin to determine the position of the pot. */ Pot = analogRead(POT_PIN); /* Is the pot in the reverse position ? */ if (Pot >= POT_REV_MIN && Pot <= POT_REV_MAX) { HCMotor.Direction(0, REVERSE); Speed = map(Pot, POT_REV_MIN, POT_REV_MAX, 10, 1024); /* Is the pot in the forward position ? */ } else if (Pot >= POT_FWD_MIN && Pot <= POT_FWD_MAX) { HCMotor.Direction(0, FORWARD); Speed = map(Pot, POT_FWD_MIN, POT_FWD_MAX, 1024, 10); /* Is the pot in the dead zone ? */ } else { Speed = 0; } /* Set the duty cycle of the clock signal in 100uS increments */ HCMotor.DutyCycle(0, Speed); }